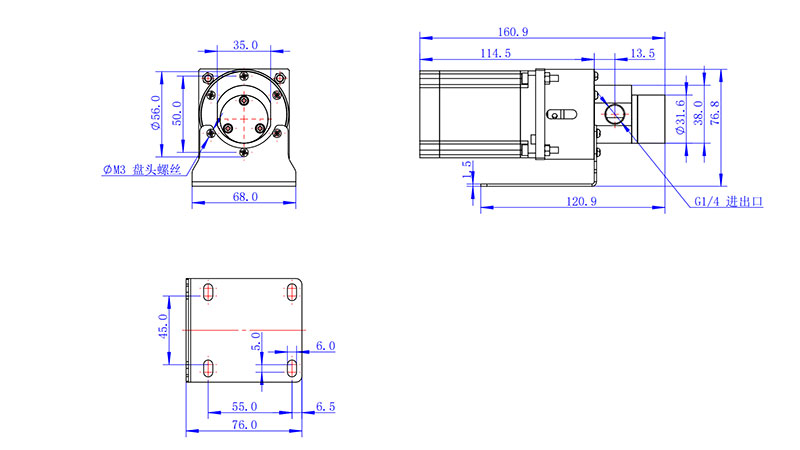

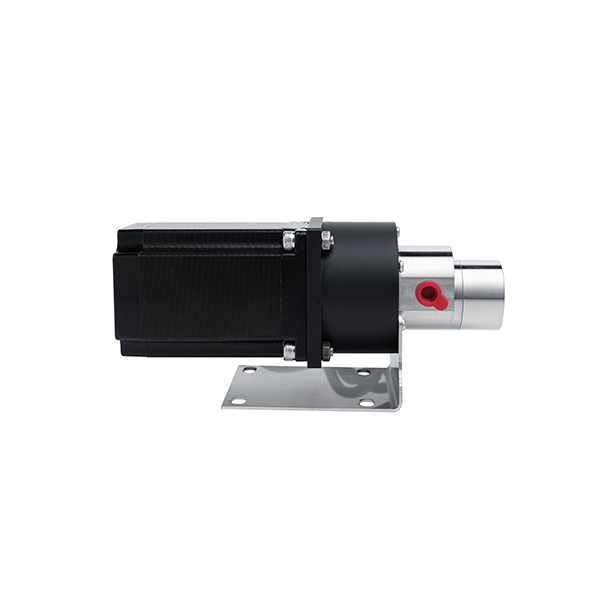

MPC010 Micro Magnetic Drive Gear Pump With 57 Stepper Motor

MPC010 micro gear pump adopts DC stepper motor, suitable for 10-700ml/min flow and 0.5-20bar pressure requirements. Applied in small flow and high precision scenario.

- No pulse accurate delivery

Through the gears to provide continuous accurate fluid transportation. with stepper motor delivery accuracy of +/-0.5%. - Strong vacuum suction capacity

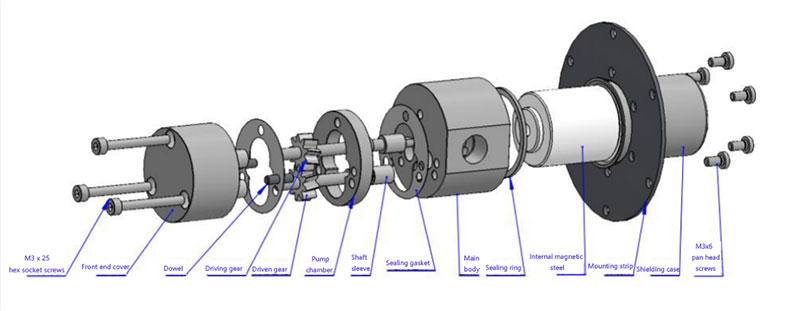

High and Stable Conveyance Pressure.High pressure delivery in low viscosity liquids. - No leakage

Magnetic drive and static O-ring seal can ensure that the medium in the pump is isolated from the outside world to achieve no leakage. - Small flow,High precison

Excellent accuracy does not accumulate errors, enabling precise positioning and repetitive motion. - Low Noise

Torque is transmitted through magnetic coupling, avoiding the mechanical contact of traditional pumps. Helical gears are designed for a smooth meshing process, reducing friction, impact and vibration.

Micro Gear Pump Descriptions

MPC010 Magnetic Drive Gear Pump powered by 57 Stepper Motor, the shaft end of the motor is connected to the external magnetic ring of the REPM to drive the magnetic gear pump. It has excellent response to start/stop/reversal, has good accuracy and does not accumulate errors from one step to the next, and is capable of precise positioning and repetitive motion, suitable for small flow and high precision application scenarios.

MICRO GEAR PUMP Model Specification

| Model | MPC | 010 | B | A | A | C | 24V | 57 |

| Position | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| 1 | Pump Series | MPB: Rubber O-Ring Seal MPC: PTFE gasket seal MPD: Direct Drive (non-magnetic) | ||||||

| 2 | Flow | 0-1L/min | ||||||

| 3 | Pump Body | A:304; B:316L; C:PPS; D:Hastelloy; E: Titanium alloy | ||||||

| 4 | Gear/Shaft | A: Gear PEEK+ shaft 316L B: Gear PEEK+ shaft ceramic C: Gear PEEK+ shaft tungsten steel D: Gear PEEK+shaft titanium alloy | ||||||

| 5 | Inlet/Outlet Thread | A: G1/8 B: G1/4 C: G3/8 D: G1/2 E: G3/4 F: G1 ” G: G1″1/4 H: M5 X: other customzations; (Letter: tooth) 1:25.4 2:34 3:38 4:50.5 5:640: Other customizations (Number: Chuck) | ||||||

| 6 | Motor | A:BL( DC Brushless Motor) B:DC(DC Brushed Motor) C:SM(Stepper Motor) D:SVCA (Servo Motor) E:ACIM 3 Phase Asynchronous Induction Motor F:ACIMB (Explosion -Proof 3 Phase Asynchronous Motor) G:BLB (Explosion Proof Brushless DC Motor) | ||||||

| 7 | Voltage | 12V/24V / 48V / 220V / 380V | ||||||

| 8 | Power | 30W/40W/60W/70W/80W/100W/110W/150W/200W/250W/300W/370W/400W/550W/750W/1000W | ||||||

MICRO GEAR PUMP Technical Paramaters

| Model | Medium Viscosity | Medium Temperature | Pressure Difference | Inlet vacuum level | Motor | Motor Speed |

| 0~3000cps | -30℃~120℃ | 20Bar | -0.85Bar | 57SM | 100-800rpm |

Get a Free Quote of Micro Magnetic Gear Pump

Related Products

Related News

Identifying and Understanding Common Problems Causes of Magnet Decoupling Magnet decoupling occurs when the magnetic coupling between the drive and […]

The type of motor drives the efficiency and reliability of micro gear pumps. AC motor vs DC motor selection influences […]

Micro pumps are miniature devices designed to control and transport small volumes of fluid with high precision. They play a […]

The rotation direction of a gear pump determines how fluid moves through the system. Incorrect rotation can disrupt flow, reduce […]

Gear pumps play a vital role in fluid transfer systems, offering reliable and efficient performance across various industries. These pumps […]

Magnetic coupling plays a crucial role in micro gear pumps by enabling leak-free fluid transfer. This innovative technology eliminates mechanical […]