MPB1000 Micro Gear Pump Magnetic Gear Pump 33ml/rev

The magnet drive principle of the MPB1000 micro magnetic drive gear pump provides a completely sealed pump chamber. No pulsation, no leakage, low noise,high performance,compact size,long lifespan.To solve the working condition of 45-100L/min flow rate, 0.5-5bar differential pressure.

- No pulse accurate delivery

Through the gears to provide continuous accurate fluid transportation. with servo and stepper motor delivery accuracy of +/-0.5%. - Strong vacuum suction capacity

High and Stable Conveyance Pressure. High pressure delivery in low viscosity liquids. - No leakage

Magnetic drive and static O-ring seal can ensure that the medium in the pump is isolated from the outside world to achieve no leakage. - Low Noise

Torque is transmitted through magnetic coupling, avoiding the mechanical contact of traditional pumps. Helical gears are designed for a smooth meshing process, reducing friction, impact and vibration. - Long Lifespan

High-performance and precision technology, advanced craftsmanship to extend its operational lifespan.

Precision Micro Gear Pump Descriptions

MPB1000series micro magnetic gear pumps are a advanced type of gear pump. The gears are made of high-performance engineering plastic PEEK, while the housing and gear shaft are crafted from premium 316L stainless steel.The sealing material is static O-ring FKM or PTFE.

FKM has stronger wear resistance and high temperature performance, and PTFE has stronger acid, alkali and corrosion resistance. Power transmission is achieved through internal and external magnetic coupling, guaranteeing leak-free conveyance. Ideal for applications requiring precise flow control, high purity, and non-contamination of liquids. CHENHUI micro magnetic gear pumps are applicable for Deionized water, methanol, urea solution, kerosene, additives, lubricating oil, lye, ammonia solution, cobalt solution, dialysate, ethylene glycol, freon, ink, glycerin, phenolic resin, curing agent, essence Fragrance, fluorinated liquid pumping system.

MICRO GEAR PUMP Model Specification

| Model | MPB | 1000 | B | A | A | 9 | I |

| Position | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| 1 | Pump Series | MPB: Rubber O-Ring Seal MPC: PTFE gasket seal | |||||

| 2 | Flow | 0-100L/min | |||||

| 3 | Pump Body | A:304; B:316L; C:PPS; D:Hastelloy; E: Titanium alloy | |||||

| 4 | Gear/Shaft | A: Gear PEEK+ shaft 316L B: Gear PEEK+ shaft ceramic C: Gear PEEK+ shaft tungsten steel D: Gear PEEK+shaft titanium alloy | |||||

| 5 | Inlet/Outlet Thread | A: G1/8 B: G1/4 C: G3/8 D: G1/2 E: G3/4 F: G1 ” G: G1″1/4 H: other customzations; (Letter: tooth) 1:25.4 2:34 3:38 4:50.5 5:640: Other customizations (Number: Chuck) | |||||

| 6 | Mounting Tab Hole Spacing | A:50 B:50.5 C:51 D:58 E:60 F:86 G:91.3 H:70 I:35 J:62 X:others (Orbicular ) 1:50 2:50.5 3:51 4:58 5:60 6:86 7:91.3 8:70 9:49.5×59 X:Others (numbers: Square) | |||||

| 7 | Internal Magnetic Drive | A:4 pole D25H19 B:4 pole D25H29 C:8 pole D25H14.5 D:8 pole D32H18.5 E:8 pole D43.6H47 F:8pole D43.6H40 G:8 pole D25H19 H:8 pole D32H31.5 I:8 pole D38.8H41.5 | |||||

MICRO GEAR PUMP Technical Paramaters

| Model | Displacement | Flow | Viscosity Range(cps) | Temperature Range | Pressure Difference | Inlet Filter | Inlet Vacuum Level | Noise |

| ml/rev | L/min | |||||||

| MPB003 | 0.10 | 0.3 | 0-3000cps | -30℃~120℃ | 0-20Bar | Recommended 400 mesh | -0.85bar | 4000RPM<60db |

| MPB005 | 0.15 | 0.5 | ||||||

| MPB015 | 0.35 | 1.5 | ||||||

| MPB030 | 0.90 | 3 | ||||||

| MPB060 | 1.41 | 6 | ||||||

| MPB075 | 1.70 | 7.5 | ||||||

| MPB100 | 3.60 | 10 | ||||||

| MPB150 | 5.40 | 15 | ||||||

| MPB300 | 6.60 | 30 | ||||||

| MPB450 | 15 | 45 | 0.2-12000cps | -10℃~90℃ | 0-5Bar | 2000RPM<60db | ||

| MPB1000 | 33 | 100 |

Get a Free Quote of High Precision Micro Magnetic Gear Pump

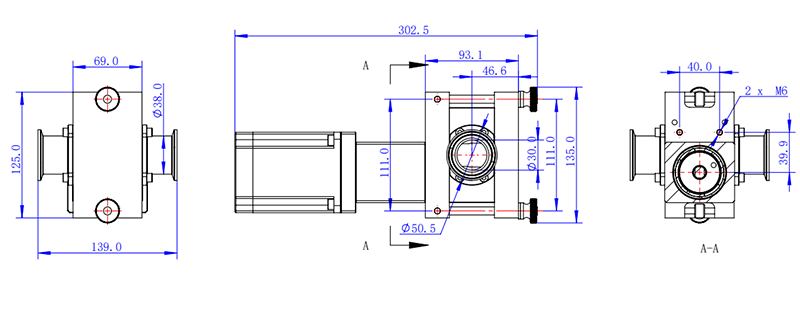

Dimensions

Performance Curve

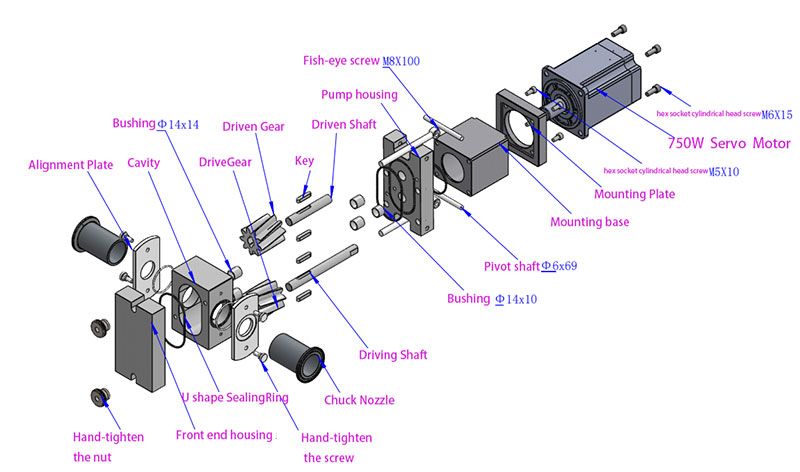

Exploded View Drawing

| 1 | Inner-hexagon screw*3 | 2 | Front end cover | 3 | Sealing ring 1 |

| 4 | Dowel*2 | 5 | Driving gear | 6 | Driven gear |

| 7 | Pump chamber | 8 | Shaft sleeve*6 | 9 | Main body |

| 10 | Sealing ring 2 | 11 | Internal magnetic steel | 12 | Shielding case |

| 13 | Mounting plate | 14 | Countersunk head screw head M3*6 |

Related Products

Related News

Choosing the right pump for an application often requires understanding the differences between a canned motor pump and a magnetic […]

Micro gear pumps play a critical role in industries requiring precise fluid transfer. Their compact design ensures efficiency in applications […]

A magnetic drive pump relies on liquid to lubricate and cool its components. Dry running deprives the pump of this […]

Magnetic drive pumps deliver reliability through their innovative design. These pumps eliminate the need for mechanical seals, ensuring leak-free operation. […]